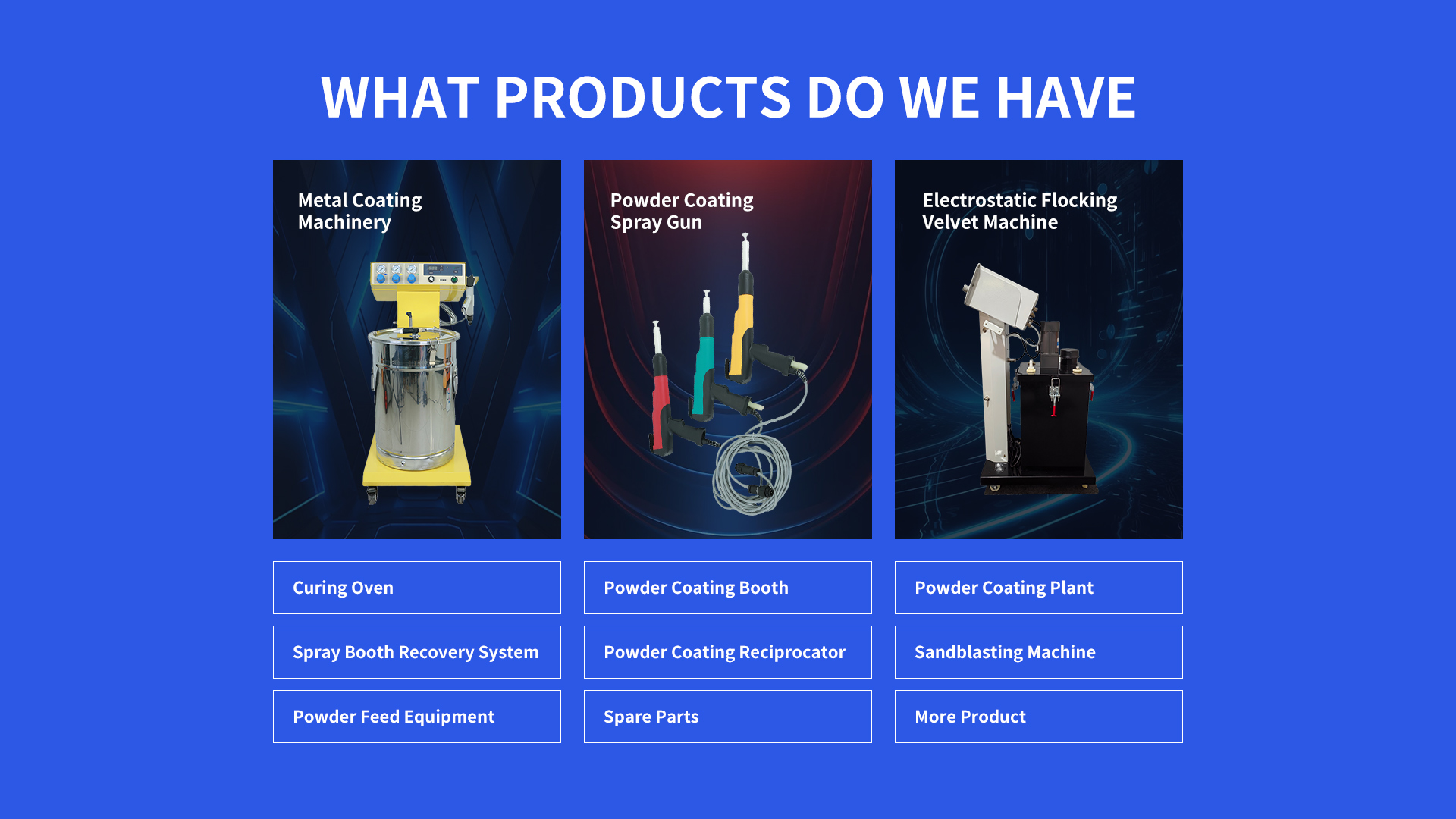

1. Introduction to Powder Coating Equipment for Home Use and Its Components

Powder Coating Equipment for Home Use is designed for DIY enthusiasts and small projects. It typically includes a spray gun, powder hopper, curing oven, and air compressor. The spray gun electrostatically charges the powder, ensuring even application, while the curing oven melts the powder into a durable, smooth finish. Compact and user-friendly, these systems are perfect for home workshops.

2. Applications of Powder Coating Equipment for Home Use

Powder Coating Equipment for Home Use is ideal for refinishing bicycles, automotive parts, furniture, and garden tools. It provides a professional-grade finish that is resistant to scratches, rust, and UV damage. Hobbyists also use it for customizing metal crafts or restoring vintage items, making it a versatile tool for creative projects.

3. Price Range of Powder Coating Equipment for Home Use

The price of Powder Coating Equipment for Home Use varies based on features and quality. Entry-level kits start at around 200,offeringbasicspraygunsandsmallovens.Mid−rangesystems,pricedbetween500 and 1,000,includeadvancedfeatureslikeadjustablevoltageandlargercuringchambers.Professional−gradesetupscancostover1,500, catering to frequent users who need industrial-level durability.

4. Proper Usage of Powder Coating Equipment for Home Use

To Powder Coating Equipment for Home Use effectively, start by cleaning and preheating the workpiece. Apply the powder evenly using the spray gun, maintaining a distance of 6–8 inches. Cure the coated item in the oven at 300–400°F for 10–20 minutes. Always follow the manufacturer’s instructions to achieve a smooth, durable finish.

5. How to Choose the Right Powder Coating Equipment for Home Use

When selecting Powder Coating Equipment for Home Use, consider the size of your projects, frequency of use, and budget. For small items, a compact oven is sufficient, while a higher-voltage spray gun is better for intricate designs. Ensure the equipment is compatible with various powder types, such as epoxy or polyester. Choose reputable brands with warranties and reliable customer support.

6. Safety Precautions for Powder Coating Equipment for Home Use

Safety is crucial when using powder coating equipment for home use. Work in a well-ventilated area to avoid inhaling fumes. Wear protective gear, including gloves, goggles, and a respirator. Keep the equipment away from flammable materials and ensure all electrical components are properly grounded. Store powders in a dry, cool place to prevent clumping.

7. Design Rationale of Powder Coating Equipment for Home Use

Powder Coating Equipment for Home Use is designed to be compact, energy-efficient, and easy to operate. Smaller ovens reduce power consumption, while lightweight spray guns improve maneuverability. Many models feature plug-and-play setups, making them accessible for beginners. These designs balance performance and affordability, catering to casual users.

8. FAQs About Powder Coating Equipment for Home Use

Q: Is powder coating eco-friendly?

A: Yes, powder coating emits minimal VOCs, making it an eco-friendly alternative to traditional liquid paints.

Q: Can I coat non-metal surfaces?

A: While metal is the primary substrate, specialized powders are available for wood and plastics.

Q: How do I maintain the spray gun?

A: Clean the spray gun after each use and inspect the nozzles for clogs to ensure consistent performance.

Q: What is the average curing time?

A: Most home ovens require 15 minutes, but thicker coatings may need additional time.

Q: Are DIY powder coats durable?

A: When applied correctly, DIY powder coats are highly durable and can withstand years of wear.

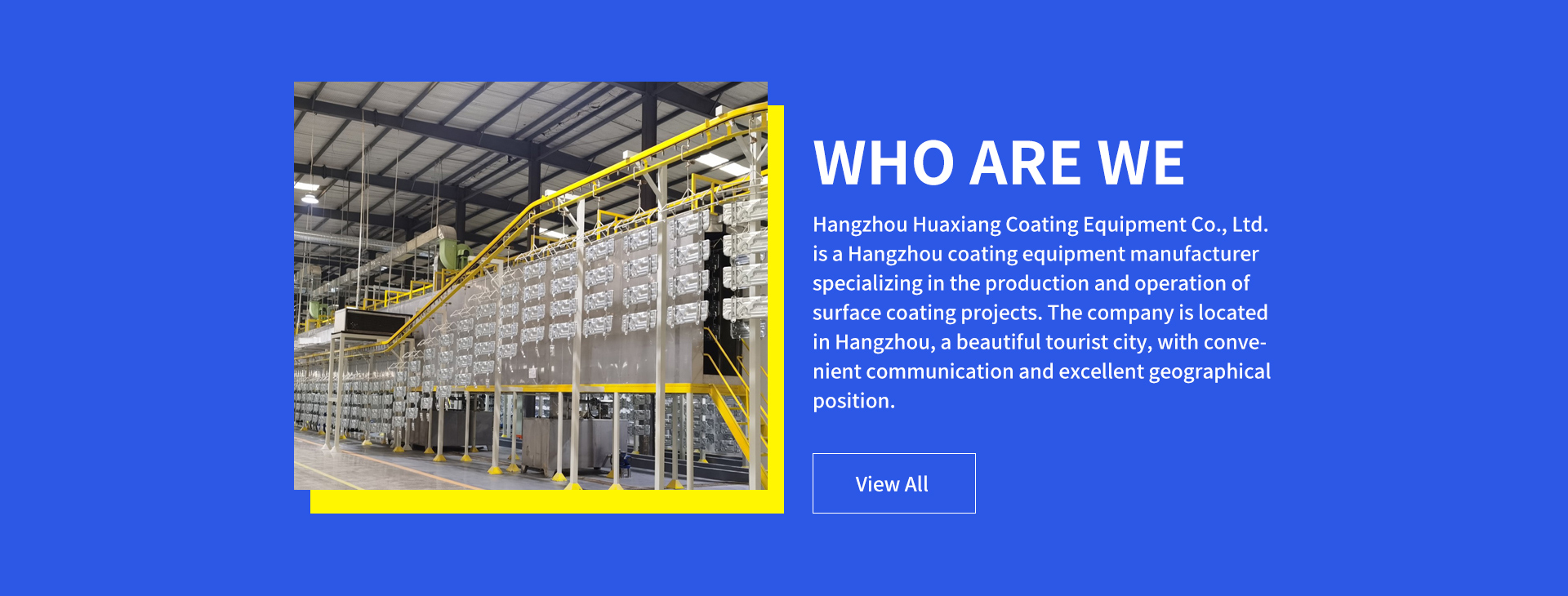

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com